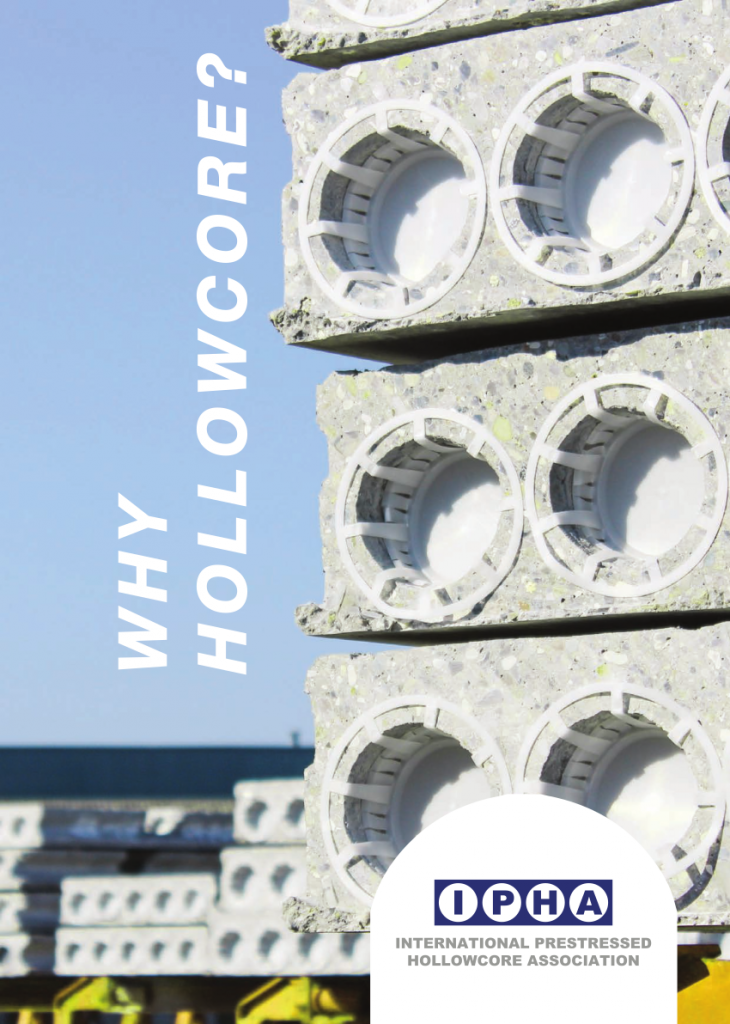

Why Hollowcore?

Sustainable construction with precast prestressed hollowcore floors.

Introduction

There is increasing awareness of the importance of guaranteeing future generations’ needs without compromising those of the present generation. Emphasis must be placed on sustainability if we are to achieve those goals.

Since some of the most basic needs of any generation are food, water, housing and transport, the construction industry is placed in a position of responsibility. It still places a considerable burden upon the environment in terms of energy consumption, use of resources, pollution and waste generation.

Designing for sustainable development not only involves using recyclable building materials and reducing energy consumption while building, but it also implies better use of available building materials and production systems with less environmental burden.

It requires products with higher performance, design systems with flexibility and adaptability to future needs, energy conservation in construction and during use of the building, environmentally friendly removal and recycling instead of noisy and dusty demolition.

Download Why Hollowcore?

The “Why Hollowcore?” brochure was created thanks to IPHA members who contributed with content ideas, and also Contiga Denmark A/S, Creagh Concrete Products Ltd, CRH Structural Concrete Belgium and Echo Precast Engineering NV, who provided illustrative photos used.

To download a PDF version, please click on the button below.

14 Advantages of Prestressed Hollow Core Slabs

Less is more

›› Reduced weight

›› Less concrete and steel per m2

40% – 50% of the element is air

›› Less requirements on foundation,

columns and beams

›› Efficient span/depth-ratio leading

to reduced story heights

›› Less waste, less mess

= less stress!

Safe to live in

›› Excellent fire resistance

›› Safer in seismic zones

›› Long–lasting and durable

Ready to go

›› Smooth surface – easy paint

›› Exposed natural surface

thanks to smooth surface

Controlled quality

›› Controlled and reliable

factory manufacturing

›› Repetitive process

›› Strict QC – procedures

›› Safe production

Sustainable

›› Reduced use of raw materials:

45% raw material saving

30% steel saving

›› Reduced waste

›› Less carbon footprint per m2

›› Easy to reuse/replace

One size fits all

›› Residential houses

›› Industrial purposes

›› Commercial buildings

Versatile

›› Adaptable to new usage in

design and final product

›› Easy to create new options

›› Flexible room design

›› Flexible buildings

Safe on site

›› Safe working platform

›› Less on-site work

(casting, RMC)

›› No construction activities

on construction site

›› Reduced site storage

›› Improved site planning

›› Less people on site and

thus less safety risks

›› Better site planning

Fast, not furious

›› High speed of building erection

›› Weather-independence

›› Next activity can start right away

›› Less neighborhood disruption

›› Adding installations almost

at the same time

Plug and play

›› Possible to embed electrical

cables, plumbing, sprinkler

services, heating and cooling

›› Drilling in less material for openings

›› Multi-purpose service options

available for the slab thickness

Strong

›› High load capacity

›› High performance in difficult

loading and handling situations

›› Extended lifetime

Size matters

›› Long spans without

intermediate supports

›› Longs spans are ideal

for open space

›› Self bearing on a large scale

Top cost benefit ratio

›› Tailor-made production

›› Optimized transport

›› Fast construction

›› Fast installation

›› Just-in-time arrival, ready to

install, lean assembly

Sounds good, feels good

›› Outstanding thermal properties

›› Capacity to heat and cool

›› Excellent acoustic results

thanks to sound absorption

›› High inertia gives more

thermal comfort

Less is More

›› Reduced weight

›› Less concrete and steel per m2

40% – 50% of the element is air

›› Less requirements on foundation,

columns and beams

›› Efficient span/depth-ratio leading

to reduced story heights

›› Less waste, less mess

= less stress!

Safe to Live In

›› Excellent fire resistance

›› Safer in seismic zones

›› Long–lasting and durable

Ready to Go

›› Smooth surface – easy paint

›› Exposed natural surface

thanks to smooth surface

Controlled Quality

›› Tailor-made production

›› Optimized transport

›› Fast construction

›› Fast installation

›› Just-in-time arrival, ready to

install, lean assembly

Sustainable

›› Reduced use of raw materials:

45% raw material saving

30% steel saving

›› Reduced waste

›› Less carbon footprint per m2

›› Easy to reuse/replace

One Size Fits All

›› Residential houses

›› Industrial purposes

›› Commercial buildings

Versatile

›› Adaptable to new usage in

design and final product

›› Easy to create new options

›› Flexible room design

›› Flexible buildings

Safe on Site

›› Safe working platform

›› Less on-site work

(casting, RMC)

›› No construction activities

on construction site

›› Reduced site storage

›› Improved site planning

›› Less people on site and

thus less safety risks

›› Better site planning

Fast, Not Furious

›› High speed of building erection

›› Weather-independence

›› Next activity can start right away

›› Less neighborhood disruption

›› Adding installations almost

at the same time

plug and play

›› Possible to embed electrical

cables, plumbing, sprinkler

services, heating and cooling

›› Drilling in less material for openings

›› Multi-purpose service options

available for the slab thickness

Strong

›› Residential houses

›› Industrial purposes

›› Commercial buildings

Size Matters

›› Long spans without

intermediate supports

›› Longs spans are ideal

for open space

›› Self bearing on a large scale

Top cost benefit Ratio

›› Tailor-made production

›› Optimized transport

›› Fast construction

›› Fast installation

›› Just-in-time arrival, ready to

install, lean assembly

Sounds good, feels good

›› Outstanding thermal properties

›› Capacity to heat and cool

›› Excellent acoustic results

thanks to sound absorption

›› High inertia gives more

thermal comfort

![NeoImage [0.6] - 20220524105806 hollowcore floor, precast concrete flooring](https://hollowcore.org/stg_658f2/wp-content/uploads/2022/06/IPHA_2022_Leuven_118-scaled.jpeg)